Building an F5 Mandolin – Part 2

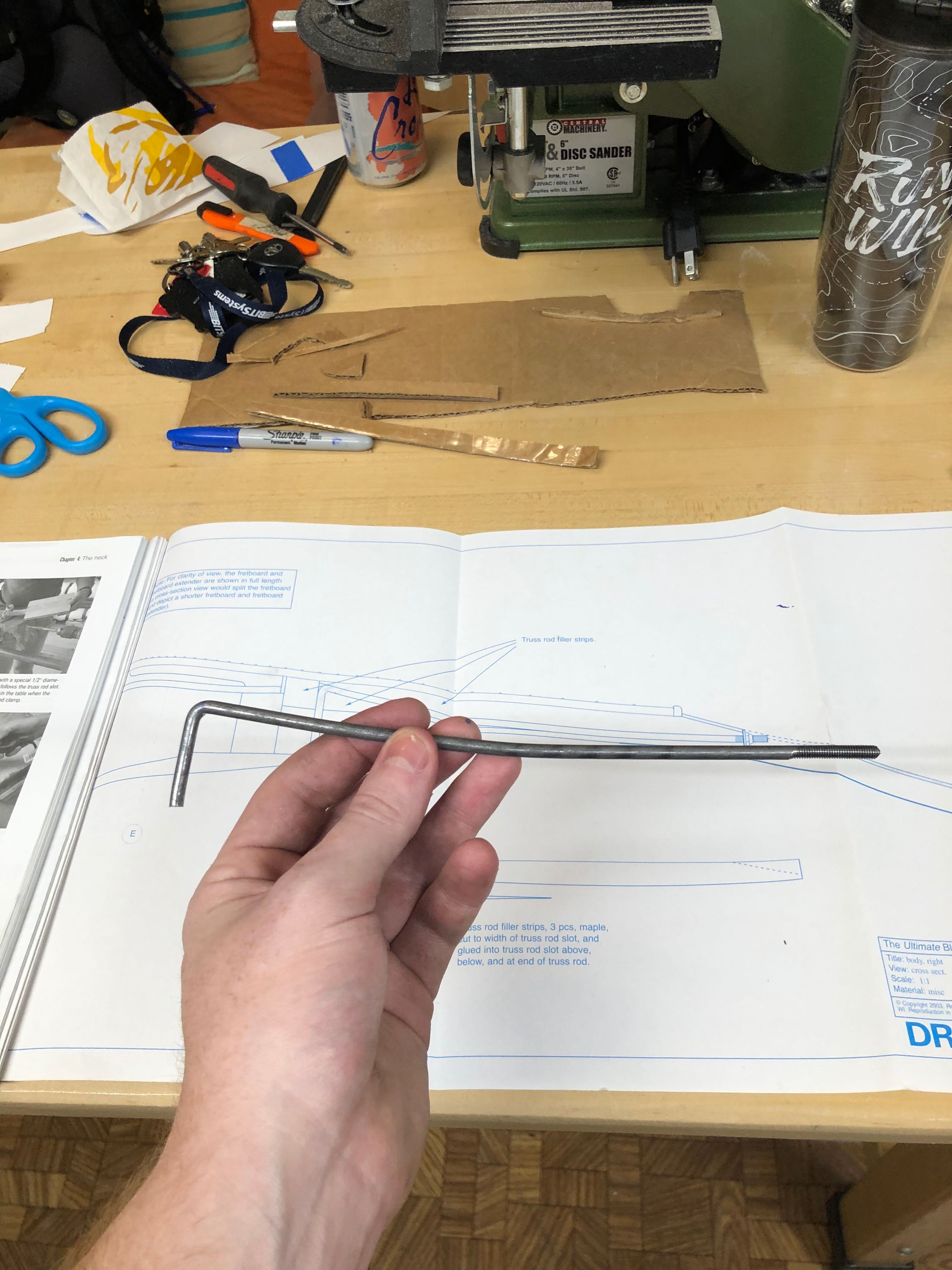

So today I dealt with installing the truss rod into the neck.

I bought a 3/16in steel rod from home depot and tried to create 1in of threads on it with a crummy harbor freight die. I cut off the bad threads and used a good Irwin die I got from Ace.

I then went through the process of creating the slot down the neck. My friend David helped me setting up a quick jig on his table saw to do a few cuts to create the slot.

I then bent the rod into shape using a hammer on a vice.

I used a dremel to create the pocket in the neck for the truss rod ’s nut to sit.

I forgot to take a picture of it, but I drilled a hole where the truss rod goes into the neck using my drill press.

I noticed after I drilled the hole that the short section of the rod was a little long, so I hacked it off such that the top of the rod with tangent with the fretboard plane.

We cut of sections of maple that fit between the truss rod and the neck to fill the gaps. We used a table sander to get them perfectly sized to fit into the slot. Finally, we clamped the whole thing together where it will sit a few days while I wait for the headstock veneer to arrive.